The important value is the current rating. Stepper motors come with a nameplate current rating, winding resistance, output torque and voltage rating. How can the same motor be run at different voltages? How does the bus voltage impact the stepper motor’s performance? In fact, identical stepper motors can be (and commonly are) operated at greatly different voltages in different systems.

#What is motor winding drivers

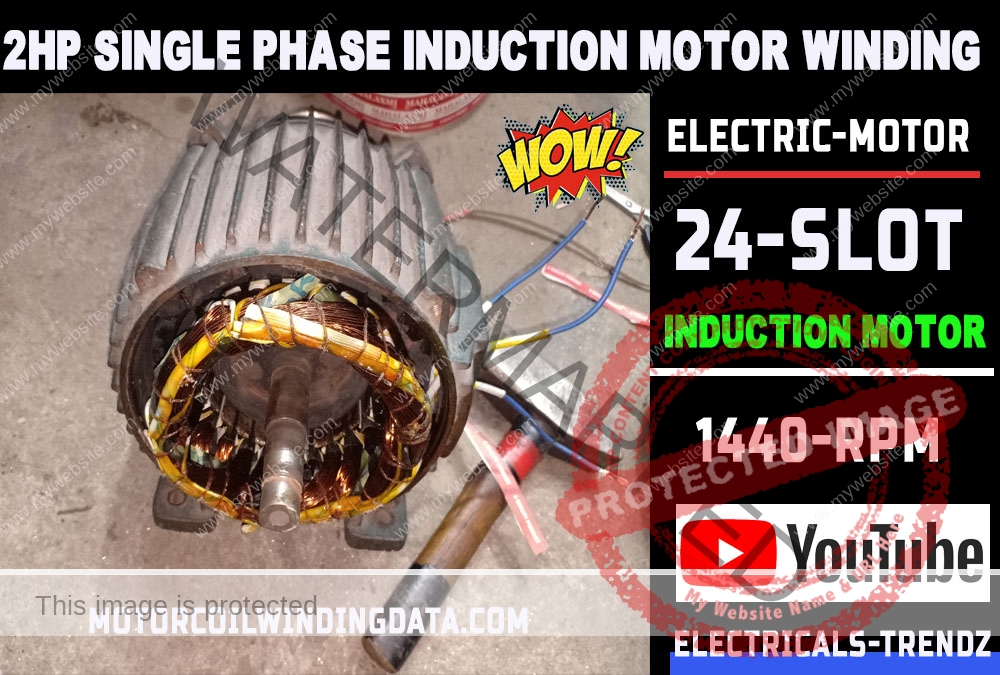

Many motor drivers use widely varying bus voltages to operate stepper motors. Stepper motor ‘voltage’ is an often confusing subject. It includes a set of coils in the slots as well as consistently spaced in the region of the winding’s margin.Posted by TWPe-jpc on Janu7:57 pm | Leave a Comment These motor windings are very important components within an electrical machine. The copper winding allows for a tiny sized motor. Aluminum can also be used but it should be thicker to hold a similar load securely. The most commonly used material for winding is copper. But in some cases, we can see the windings like bare copper but it’s simply coated with enamel. The wire utilized within the windings should be protected. From the above information finally, we can conclude that windings are made with copper wires which are wound around a core to make or obtain electromagnetic energy. Thus, this is all about an overview of the motor winding theory. Generally, if it is open then it will be above 2K ohms or infinite. If we observe the reading like zero, and a short among phases occurs. Place meter on ohms and generally the range can be expected from 3 to 2 ohms. With the help of Ohm meter, detach the power supply from the motor. The reading of the motor winding machine can be displayed on the multimeter screen that is resistance in ohms. Similarly, connect the negative terminal which is in black color to the negative terminal of the windings of the motor. Connect the positive terminal of the multimeter which is in red color to the positive terminal of the windings of the motor. The motor winding wire calculation can be done using an ohmmeter. Please refer to the link to know more about Lap Winding & Wave Winding. The number of parallel ports can be equal in the direction of the number of brushes, which is used for high-voltage, and low-current machines. The conductors in this type of winding can be connected with two parallel lanes in a machine pole.

The primary armature coil’s end part can be associated with the starting part of the next armature coil commutator part with some distance. Wave winding includes parallel lanes among the two brushed like positive & negative.

The motor winding types are two types which include the following. Generally, these are power-driven with electromagnetic induction. Some kinds of motors include conductors with thicker metal like sheets of metal otherwise bars generally copper, otherwise aluminum. A shaded pole motor includes a winding which is placed around the pole part that holds up the magnetic field phase. In the non-salient pole configuration, the winding can be dispersed within slots of pole face. In the salient pole configuration machine, the magnetic field pole can be generated produced with a winding wound approximately under the pole face. The motor winding diagram is shown below. Electric machines are available in two fundamental magnet field pole configurations namely salient pole as well as a non-salient pole.

The electric motor winding definition is, windings in electric motors are wires that are placed within coils, generally enclosed around a coated flexible iron magnetic core to shape magnetic poles while strengthened with the current.

0 kommentar(er)

0 kommentar(er)